PNEUMATIC CABLE CONTACTING

For cable modules with open end

Innovative cable testing

Take your cable production and testing to the next level

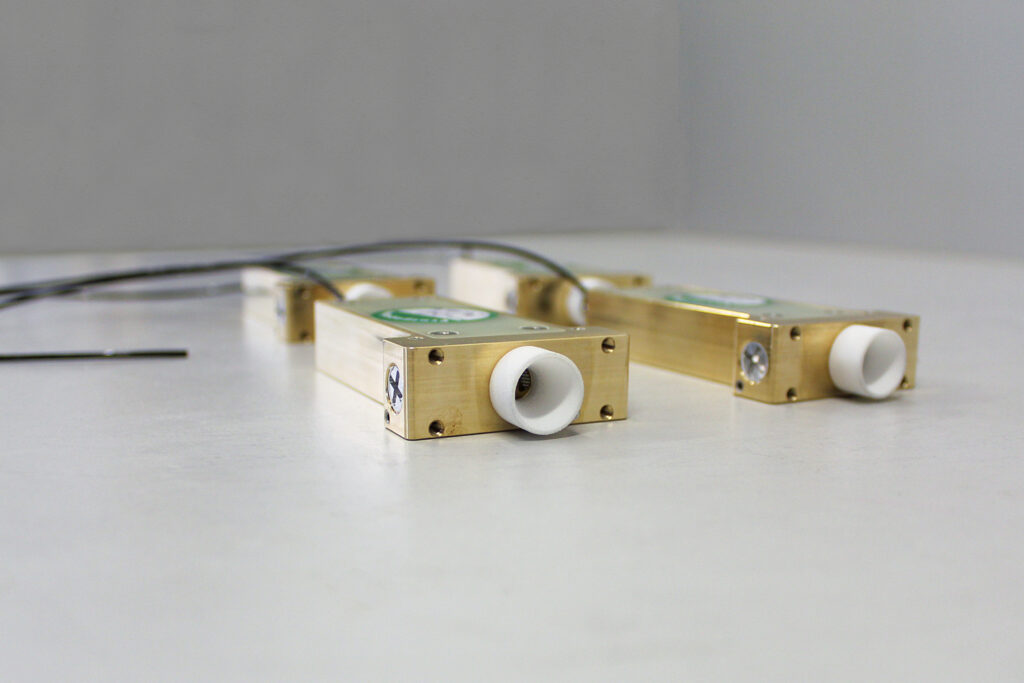

Nowadays and in the future, cables are indispensable in almost all areas of life. They not only transmit energy or signals, but also fulfill specific requirements and transmissions depending on their intended use. By using fine needles, our pneumatic cable contacting system offers a contamination-free and maintenance-free solution for testing open-ended cable modules without having to strip them before the test.

Guarantee first-class quality with our efficient and precise pneumatic cable contacting!

Unique selling points!

For efficient and non-destructive tests

Our innovative technology is designed to adapt seamlessly to the individual requirements of a wide range of production environments. Available both as a stand-alone module and as a fully configurable workstation, it offers maximum flexibility and can be easily integrated into existing systems.

The modular design enables uncomplicated adaptation and expansion. In this way, we guarantee comprehensive, safe and reliable testing of cable connections without damaging the sensitive cable ends.

ORDER NOW!

Your advantages at a glance

- Contamination and maintenance-free testing

- No cable stripping necessary

- Efficient and safe testing process

- No damage to the sensitive cable ends

- Available both as a single module and as a fully configurable workstation

Types

Available versions

1-4 mm²

Cross section

In order to meet the requirements of applications with higher power requirements, this version is also available as a high-frequency version.

6-16 mm²

Cross section

In order to meet the requirements of applications with higher power requirements, this version is also available as a high-frequency version.

On request

Cross section

Um auch spezifische Anforderungen und individuelle Bedürfnisse zu erfüllen, sind weitere Querschnittsgrößen auf Anfrage erhältlich.

Functionality

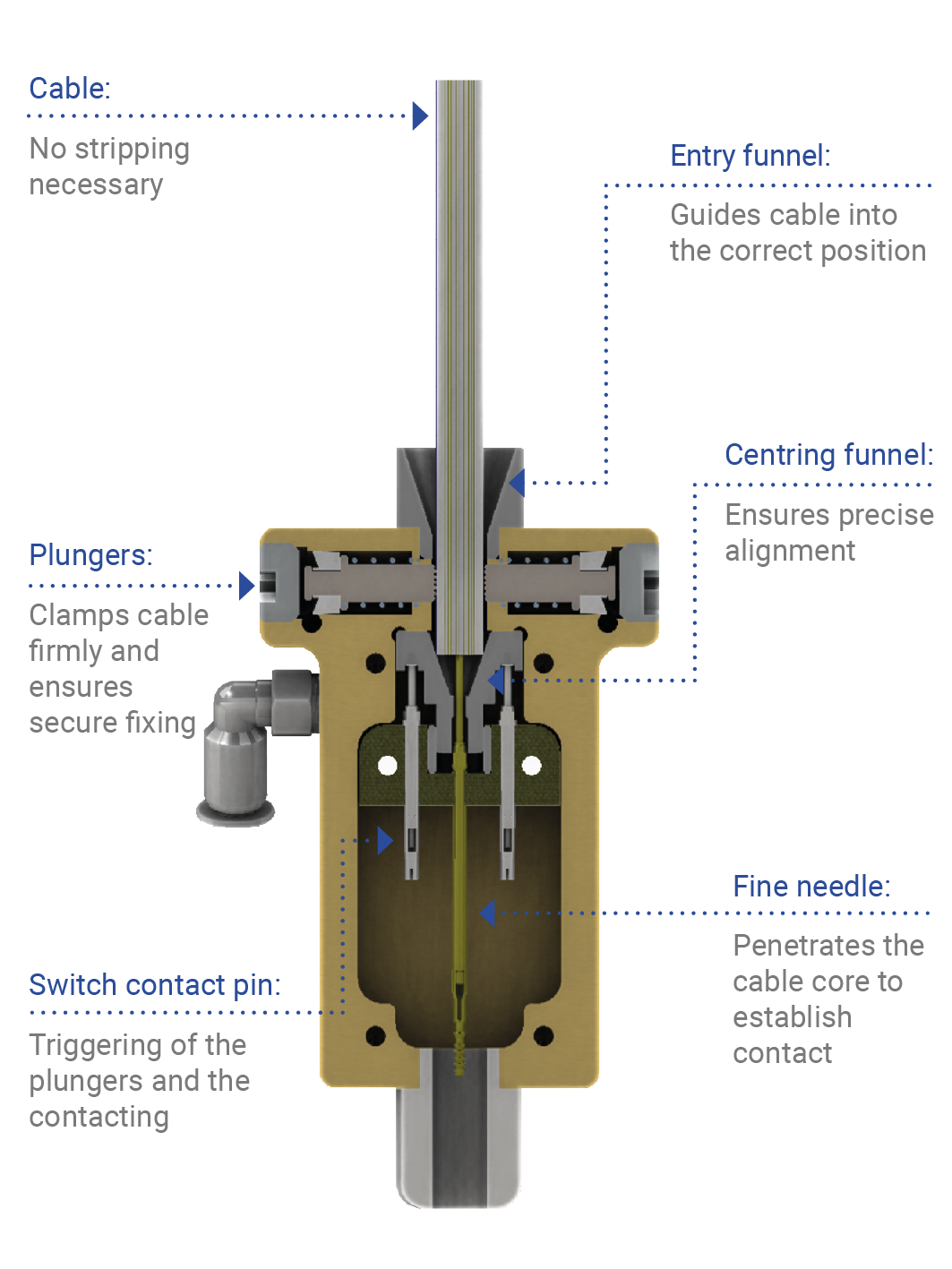

Pneumatic cable contacting

Pneumatic cable contacting is an advanced technology for testing open-ended cable modules that aims to make the testing process efficient and safe. Thanks to the automated locking mechanism, the test can be performed both manually and automatically.

How our technology works

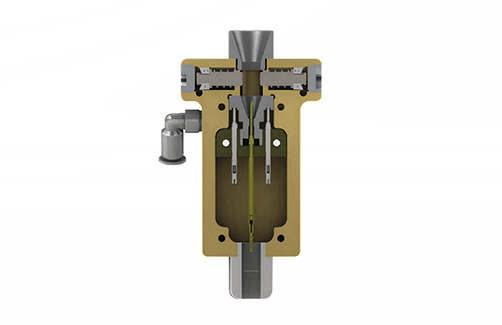

1. Cable entry:

The cable to be tested is inserted into the test device without prior stripping.

2. Centering and fixing:

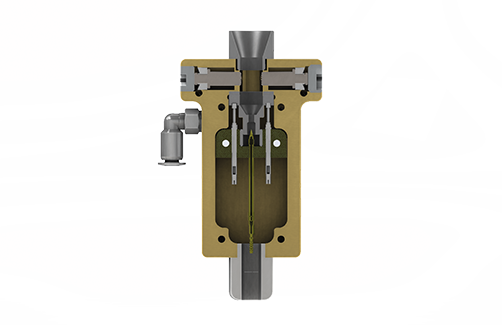

The cable is brought into the correct position via an insertion funnel, while the centering funnel underneath ensures precise alignment. Once the cable has been centered, a switch contact pin automatically activates two pneumatic pistons that clamp the cable. This clamping ensures that the cable is correctly fixed and does not slip during the test.

3. Signaling and contacting:

As soon as the cable has been securely fixed, a fine needle, controlled by another switching contact pin, penetrates the core of the cable. This is designed in such a way that it does not damage the insulation of the cable and therefore has no effect on its integrity. As soon as the contact is successfully established, the test process starts automatically.

4. Test execution:

Depending on the requirements, various tests such as continuity tests, resistance measurements or short-circuit tests are carried out to ensure the functionality and quality of the cable.

5. End of test and removal:

Once the test is complete, the cable clamp is released by an external signal, e.g. from a tester or button, so that the cable can be removed. The entire process is designed to minimize manual intervention and maximize efficiency.

Thanks to this structured and automated approach, pneumatic cable contacting offers a reliable, fast and safe method of testing individual cables that is suitable for both individual applications and complex production environments.

Order options

Give us a call or send us an e-mail! We are always there for you.

Phone +49 7031 7460-0

Mail: info@leitec.info